Product categories

- Glass fiber reinforced plastic storage tank

- 0

- 0

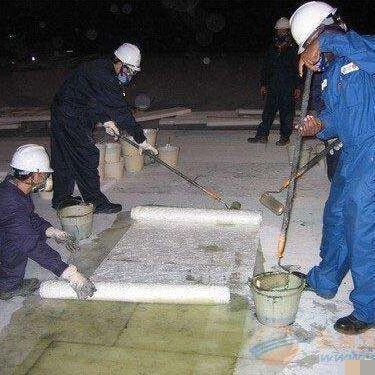

- Anticorrosion construction of glass fiber reinforced plastics

- Glass fiber reinforced plastic pipe

- 0

- 0

- 0

- frp grating

- Jiangsu glass fiber reinforced plastic corrosion protection engineering company

- 0

- diaosu

- 0

- 0

- Integrated prefabricated pumping station

- FRP manufacturers

Contact us

- Add: Suzhou, Changzhou, Wuxi, Shanghai FRP anti-corrosion products

- Tel: 【加微信时须说明您的单位名称和手机号码】

- Fax: 【推销勿扰】【不接同行业务】

- Email: 主要为长三角地区提供玻璃钢防腐制品定制

Product show

Glass fiber reinforced plastic corrosion protection project - Jiangsu glass fiber reinforced plastic corrosion protection engineering company

Product Numbers:2016121321148

Price:Glass fiber reinforced plastic corrosion protectio

Product introduction:Jiangsu glass steel anti-corrosion engineering company with FRP pipe, glass steel tank, glass steel cooling tower, glass steel desulfurization tower, mist purification tower, waste gas treatment equipment, glass steel chimney etc.

Glass fiber reinforced plastic corrosion protection project is made of carbon steel, concrete or other substrate surface of glass fiber reinforced plastic, to prevent damage or deterioration of the substrate in the medium or environment, known as "glass fiber reinforced plastic anti-corrosion".

Glass steel anti-corrosion engineering with corrosion resistant resin and glass fiber or glass fiber cloth as the anticorrosion layer, with unsaturated polyester resin and E-glass fiber cloth reinforced layer, corrosion resistance, high strength, long service life, is widely used in chemical industry, metallurgy, electric power, electronics, electroplating, oil printing and dyeing, machinery, environmental protection, sewage treatment and other industries.

Advantages of glass fiber reinforced plastic corrosion protection project

1, lightweight glass steel: the proportion of only 1.4-2.0, while the tensile strength of steel fiber wrapped glass up to 300-500Mpa, exceeding the ultimate strength of ordinary steel, such as the calculation of strength, also has reached or exceeded some special alloy steel, it can be used as the main structure material anti-corrosion equipment, and has shipped

Advantages of convenient transportation, installation and maintenance.

2, excellent corrosion resistance: one of the biggest characteristics of glass steel, is good corrosion resistance. Through the choice of the type and grade of the resin, the suitable molding process can be used to produce a variety of acid, alkali, salt and organic solvent glass fiber reinforced plastic products.

3, good surface performance and easy cleaning and sterilization properties: because the glass steel is integrally molded, seamless, smooth inner wall, and chemical medium, there is little corrosion and scaling phenomenon of the surface, but do not breed bacteria and microorganisms. Therefore do not pollute the medium, very easy to clean, by the food and Drug Administration

Special inspection, glass steel has reached the requirements of food brewing, pharmaceutical industry.

4, good design: glass steel can change its raw materials, in proportion to the number and arrangement of a reinforced material, composite materials to meet different performance requirements.

5, good construction process: not cured resin and reinforced materials have the ability to change shape, therefore, can be easily processed into the desired shape by different molding methods and tooling. This feature is the most suitable for large, complex equipment and construction requirements, applicable to the field of construction and assembly.

6, anti aging, flame retardant: glass fiber reinforced plastic is the category of products, matrix materials, natural aging and burning problem. But the world after 60 years, Chinese after more than 30 years of research, it has been solved, reinforced materials and coupling agent treatment, the use of 50 years, the bending strength of insurable lasting

64-46%, tensile strength retention rate at 71.2%, such as adding antioxidant, anti-aging performance is better; the glass substrate by adding flame retardant agent and flame retardant resin adding flame retardant, the oxygen index reached 34-36, fully meet the requirements of fire retardant fermentation equipment.

7, low comprehensive cost: glass fiber reinforced plastic as a new functional material, as a result of the high prices of raw materials used. Generally speaking, the price of FRP equipment is higher than that of carbon steel equipment and some plastic equipment, but lower than that of stainless steel and other non-ferrous metal equipment. But because of light weight, good corrosion resistance, the glass fiber reinforced plastic

Long service life, less maintenance advantages, its installation and use cost and low comprehensive cost; and for some complicated working conditions or severe equipment, can be used to each in his element for heating coil, such as stainless steel or titanium, lined with plastic material, so as to have a good performance and can reduce the cost..

The. Layer thickness to adjust different media and loads. Welcome to Jiangsu glass fiber reinforced plastic corrosion protection engineering company

Substrate treatment method for glass fiber reinforced plastic corrosion protection engineering

1, acid (base oil for more): metal rust remover cleaning oil steel structure surface, and then rinse with water, and with the scrub brush, which can remove more oil.

Methods: 2, mechanical grinding machine with clear surface oxide skin, rust steel structure membrane residual sand, welding slag, dust, oil and other substances, to make the coating firmly attached on the surface of the workpiece, it must be cleaned prior to coating on the surface of the workpiece, otherwise, not only affects the binding force of the coating with the base metal and corrosion resistance, but also to the base metal in even with protective coatings are able to corrosion, the coating peeling effect, mechanical properties and service life of steel structure. Therefore, the surface treatment before construction of the steel structure is to obtain a good quality of the protective layer, and to extend the service life of the steel structure is an important guarantee for the construction of steel structure.

Certificate and measures.

Working conditions of glass fiber reinforced plastic corrosion protection engineering

1, the humidity is too large to add the desiccant, the temperature is too low, should be used to increase the temperature measure.

2, glass steel construction, should be strictly in accordance with the design requirements to check the quality of the work process, and to do a good job in the construction record.

3, the concrete base surface requires strong, dense, smooth, can not have a shell crack and other unqualified phenomenon.

4, raw materials in the form of pipe to the operation of the delivery, the construction site ready to have a fixed capacity of the batching equipment.

Notice for corrosion protection of glass fiber reinforced plastics

1, the construction site should be kept clean, after the end of the operation to clean up the remnants of flammable, explosive and other debris.

2, glass steel floor maintenance time is more than 10 days, more than 20 days of storage tank, room temperature curing can use time is 30 days.

3, the construction site should maintain good ventilation, the configuration of fire equipment, and the prohibition of fireworks warning signs to ensure safety.

4, strictly control the construction environment and technical conditions, the ambient temperature is greater than 12 degrees Celsius, humidity is not greater than 80%, to ensure quality, not to drive the progress.

5, the corner, the door

Glass steel anti-corrosion engineering with corrosion resistant resin and glass fiber or glass fiber cloth as the anticorrosion layer, with unsaturated polyester resin and E-glass fiber cloth reinforced layer, corrosion resistance, high strength, long service life, is widely used in chemical industry, metallurgy, electric power, electronics, electroplating, oil printing and dyeing, machinery, environmental protection, sewage treatment and other industries.

Advantages of glass fiber reinforced plastic corrosion protection project

1, lightweight glass steel: the proportion of only 1.4-2.0, while the tensile strength of steel fiber wrapped glass up to 300-500Mpa, exceeding the ultimate strength of ordinary steel, such as the calculation of strength, also has reached or exceeded some special alloy steel, it can be used as the main structure material anti-corrosion equipment, and has shipped

Advantages of convenient transportation, installation and maintenance.

2, excellent corrosion resistance: one of the biggest characteristics of glass steel, is good corrosion resistance. Through the choice of the type and grade of the resin, the suitable molding process can be used to produce a variety of acid, alkali, salt and organic solvent glass fiber reinforced plastic products.

3, good surface performance and easy cleaning and sterilization properties: because the glass steel is integrally molded, seamless, smooth inner wall, and chemical medium, there is little corrosion and scaling phenomenon of the surface, but do not breed bacteria and microorganisms. Therefore do not pollute the medium, very easy to clean, by the food and Drug Administration

Special inspection, glass steel has reached the requirements of food brewing, pharmaceutical industry.

4, good design: glass steel can change its raw materials, in proportion to the number and arrangement of a reinforced material, composite materials to meet different performance requirements.

5, good construction process: not cured resin and reinforced materials have the ability to change shape, therefore, can be easily processed into the desired shape by different molding methods and tooling. This feature is the most suitable for large, complex equipment and construction requirements, applicable to the field of construction and assembly.

6, anti aging, flame retardant: glass fiber reinforced plastic is the category of products, matrix materials, natural aging and burning problem. But the world after 60 years, Chinese after more than 30 years of research, it has been solved, reinforced materials and coupling agent treatment, the use of 50 years, the bending strength of insurable lasting

64-46%, tensile strength retention rate at 71.2%, such as adding antioxidant, anti-aging performance is better; the glass substrate by adding flame retardant agent and flame retardant resin adding flame retardant, the oxygen index reached 34-36, fully meet the requirements of fire retardant fermentation equipment.

7, low comprehensive cost: glass fiber reinforced plastic as a new functional material, as a result of the high prices of raw materials used. Generally speaking, the price of FRP equipment is higher than that of carbon steel equipment and some plastic equipment, but lower than that of stainless steel and other non-ferrous metal equipment. But because of light weight, good corrosion resistance, the glass fiber reinforced plastic

Long service life, less maintenance advantages, its installation and use cost and low comprehensive cost; and for some complicated working conditions or severe equipment, can be used to each in his element for heating coil, such as stainless steel or titanium, lined with plastic material, so as to have a good performance and can reduce the cost..

The. Layer thickness to adjust different media and loads. Welcome to Jiangsu glass fiber reinforced plastic corrosion protection engineering company

Substrate treatment method for glass fiber reinforced plastic corrosion protection engineering

1, acid (base oil for more): metal rust remover cleaning oil steel structure surface, and then rinse with water, and with the scrub brush, which can remove more oil.

Methods: 2, mechanical grinding machine with clear surface oxide skin, rust steel structure membrane residual sand, welding slag, dust, oil and other substances, to make the coating firmly attached on the surface of the workpiece, it must be cleaned prior to coating on the surface of the workpiece, otherwise, not only affects the binding force of the coating with the base metal and corrosion resistance, but also to the base metal in even with protective coatings are able to corrosion, the coating peeling effect, mechanical properties and service life of steel structure. Therefore, the surface treatment before construction of the steel structure is to obtain a good quality of the protective layer, and to extend the service life of the steel structure is an important guarantee for the construction of steel structure.

Certificate and measures.

Working conditions of glass fiber reinforced plastic corrosion protection engineering

1, the humidity is too large to add the desiccant, the temperature is too low, should be used to increase the temperature measure.

2, glass steel construction, should be strictly in accordance with the design requirements to check the quality of the work process, and to do a good job in the construction record.

3, the concrete base surface requires strong, dense, smooth, can not have a shell crack and other unqualified phenomenon.

4, raw materials in the form of pipe to the operation of the delivery, the construction site ready to have a fixed capacity of the batching equipment.

Notice for corrosion protection of glass fiber reinforced plastics

1, the construction site should be kept clean, after the end of the operation to clean up the remnants of flammable, explosive and other debris.

2, glass steel floor maintenance time is more than 10 days, more than 20 days of storage tank, room temperature curing can use time is 30 days.

3, the construction site should maintain good ventilation, the configuration of fire equipment, and the prohibition of fireworks warning signs to ensure safety.

4, strictly control the construction environment and technical conditions, the ambient temperature is greater than 12 degrees Celsius, humidity is not greater than 80%, to ensure quality, not to drive the progress.

5, the corner, the door

No previous

NEXT:bjs-x