Product categories

- Glass fiber reinforced plastic storage tank

- 0

- 0

- Anticorrosion construction of glass fiber reinforced plastics

- Glass fiber reinforced plastic pipe

- 0

- 0

- 0

- frp grating

- Jiangsu glass fiber reinforced plastic corrosion protection engineering company

- 0

- diaosu

- 0

- 0

- Integrated prefabricated pumping station

- FRP manufacturers

Contact us

- Add: Suzhou, Changzhou, Wuxi, Shanghai FRP anti-corrosion products

- Tel: 【加微信时须说明您的单位名称和手机号码】

- Fax: 【推销勿扰】【不接同行业务】

- Email: 主要为长三角地区提供玻璃钢防腐制品定制

Product show

The advantages of concrete filled FRP chimney

Product Numbers:20173412137

Price:FRP chimney

Product introduction:Jiangsu glass steel chimney factory (Wuxi FRP chimney, Suzhou FRP chimney, Changzhou FRP chimney, Nantong FRP chimney) Shanghai FRP tanks, FRP pipe, glass steel anti-corrosion, toughened glass tank and exhaust gas treatment equipm

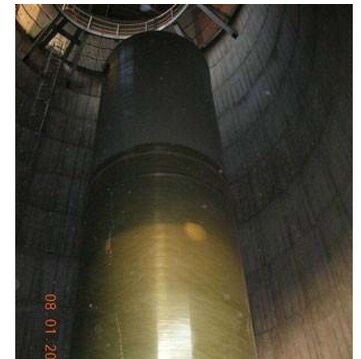

Glass fiber reinforced plastic chimney is the main way to discharge coal gas in thermal power, metallurgy and other industries. In the thermal power industry, for example, in the past, the thermal power industry is often only to take measures to remove coal dust emissions, that is, through high chimney exhaust gas into the surrounding atmosphere. Today, due to the strict control of environmental protection requirements of sulfur dioxide emissions, the need for the desulfurization of flue gas, most of the current thermal power industry wet desulfurization. In the wet desulfurization process of flue gas, while containing more sulfur dioxide, but high temperature flue gas enters the chimney, up to 130~160 DEG C, only a small amount of the formation of the phenomenon of flue gas condensation, the chimney corrosion is not very high. However, after wet desulfurization, the flue gas temperature dropped to 50~80 DEG C, and the moisture content of the flue gas was higher, which led to the increase of the corrosion rate. Although the temperature of flue gas wet desulfurization to 50-80 DEG C, but in the design of chimney flue gas temperature will often consider an emergency state without wet desulfurization (about 150 DEG C) and temperature (accident nearly 200 DEG C), so the requirements of corrosion resistance and temperature resistance have high wet desulphurization chimney. The advantages of concrete filled FRP chimney

In order to solve the problem of serious corrosion of chimney wall due to the installation of wet desulfurization equipment, a large number of domestic and foreign researchers have done a lot of research and engineering tests. Currently used anticorrosion materials is acid resistant brick and acid resistant cement and steel titanium composite structure, steel and stainless steel composite field, steel coating materials and hard alloy liner e-276. Compared with other types of glass fiber reinforced plastic chimney, it has the advantages of corrosion resistance, low investment, short construction period, light weight and long service life. The advantages of concrete filled FRP chimney

In order to solve the problem of serious corrosion of chimney wall due to the installation of wet desulfurization equipment, a large number of domestic and foreign researchers have done a lot of research and engineering tests. Currently used anticorrosion materials is acid resistant brick and acid resistant cement and steel titanium composite structure, steel and stainless steel composite field, steel coating materials and hard alloy liner e-276. Compared with other types of glass fiber reinforced plastic chimney, it has the advantages of corrosion resistance, low investment, short construction period, light weight and long service life. The advantages of concrete filled FRP chimney