Product categories

- Glass fiber reinforced plastic storage tank

- 0

- 0

- Anticorrosion construction of glass fiber reinforced plastics

- Glass fiber reinforced plastic pipe

- 0

- 0

- 0

- frp grating

- Jiangsu glass fiber reinforced plastic corrosion protection engineering company

- 0

- diaosu

- 0

- 0

- Integrated prefabricated pumping station

- FRP manufacturers

Contact us

- Add: Suzhou, Changzhou, Wuxi, Shanghai FRP anti-corrosion products

- Tel: 【加微信时须说明您的单位名称和手机号码】

- Fax: 【推销勿扰】【不接同行业务】

- Email: 主要为长三角地区提供玻璃钢防腐制品定制

Product show

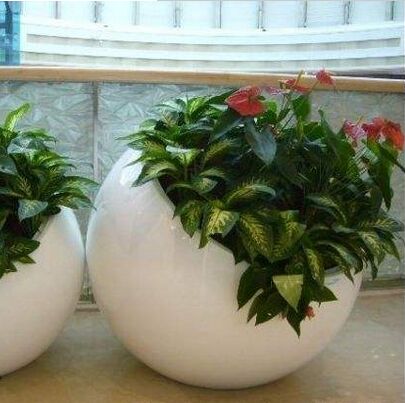

Advantages and disadvantages of glass fiber reinforced plastic flowerpots

Product Numbers:20176195620

Price:FRP flowerpot

Product introduction:Jiangsu FRP corrosion protection factory. Glass fiber reinforced plastic products -- glass fiber reinforced plastic flowerpot. Suzhou Wuxi Changzhou Nantong Shanghai mist purification tower / exhaust gas purification tower / glass

First, the advantages of glass fiber reinforced plastic flowerpot:

1. lightweight high strength;

The relative density is between 1.5~2.0 and only 1/4~1/5 of carbon steel, but the tensile strength is close to or even higher than that of carbon steel, while the specific strength can be compared with that of advanced alloy steel. As a result, aviation, rockets, aerospace vehicles, high pressure vessels, and other applications that need to reduce weight have excellent results. The tensile, flexural and compressive strengths of some epoxy FRP can reach over 400Mpa. Density, strength and specific strength of some materials.

2. good corrosion resistance;

FRP is a good corrosion resistant material. It has good resistance to atmosphere, water and acid, alkali, salt, various kinds of oils and solvents. Has been applied to all aspects of chemical corrosion, is replacing carbon steel, stainless steel, wood, nonferrous metals and so on.

3. good electrical performance;

It is a good insulating material used for making insulators. High dielectric protection can be maintained at high frequencies. Microwave permeability is good, and has been widely used in radome.

4. good thermal performance;

FRP has a low thermal conductivity and is 1.25~1.67kJ/ (M. H. K) at room temperature. Only metal 1/100~1/1000 is a good thermal insulating material. It is an ideal thermal protection and ablative material in the instantaneous ultra high temperature, which can protect the spacecraft from the erosion of high velocity air at temperatures above 2000 degrees celsius.

5., good design;

A. can flexibly design all kinds of structural products according to the needs, to meet the use requirements, and make the products have a good integrity.

B. can fully select materials to meet the performance of products, such as: corrosion resistance, high temperature resistance, high strength, good dielectric properties, etc..

C. good manufacturability.

D. can flexibly select the molding process according to the shape, technical requirements, uses and quantities of the products.

E. process is simple, can be shaped at once, the economic effect is outstanding, especially for the complex shape, difficult to shape a small number of products, more prominent its superior technology.

Two. Disadvantages of glass fiber reinforced plastic flower pots;

1. low modulus of elasticity;

The elastic modulus of FRP is two times larger than the wood, but the ratio of steel (E=2.1 * 106) is 10 times smaller, so in the product structure often feel lack of rigidity, easy deformation, can be made into a thin shell structure, sandwich structure, but also by high modulus fiber or reinforcement form to make up.

2. long term heat resistance is poor;

General FRP can not be used for a long time at high temperature, the general polyester FRP at 50 degrees above, the intensity decreased significantly, generally only under 100 degrees Celsius use; general type epoxy FRP at 60 degrees above, the intensity has decreased significantly. But it is possible to choose the high temperature resistant resin to make the long working temperature at 200~300 centigrade possible.

3. aging phenomenon;

Aging is a common defect of plastics, FRP is no exception, in the ultraviolet, sand, rain and snow, chemical media, mechanical stress, etc., easily lead to performance degradation.

The shear strength between the 4. layers is low

The interlaminar shear strength is borne by the resin, so it is very low. The adhesive force between layers can be improved by choosing the process and using coupling agent. The most important thing is to avoid shearing the interlayer when the product is designed.

1. lightweight high strength;

The relative density is between 1.5~2.0 and only 1/4~1/5 of carbon steel, but the tensile strength is close to or even higher than that of carbon steel, while the specific strength can be compared with that of advanced alloy steel. As a result, aviation, rockets, aerospace vehicles, high pressure vessels, and other applications that need to reduce weight have excellent results. The tensile, flexural and compressive strengths of some epoxy FRP can reach over 400Mpa. Density, strength and specific strength of some materials.

2. good corrosion resistance;

FRP is a good corrosion resistant material. It has good resistance to atmosphere, water and acid, alkali, salt, various kinds of oils and solvents. Has been applied to all aspects of chemical corrosion, is replacing carbon steel, stainless steel, wood, nonferrous metals and so on.

3. good electrical performance;

It is a good insulating material used for making insulators. High dielectric protection can be maintained at high frequencies. Microwave permeability is good, and has been widely used in radome.

4. good thermal performance;

FRP has a low thermal conductivity and is 1.25~1.67kJ/ (M. H. K) at room temperature. Only metal 1/100~1/1000 is a good thermal insulating material. It is an ideal thermal protection and ablative material in the instantaneous ultra high temperature, which can protect the spacecraft from the erosion of high velocity air at temperatures above 2000 degrees celsius.

5., good design;

A. can flexibly design all kinds of structural products according to the needs, to meet the use requirements, and make the products have a good integrity.

B. can fully select materials to meet the performance of products, such as: corrosion resistance, high temperature resistance, high strength, good dielectric properties, etc..

C. good manufacturability.

D. can flexibly select the molding process according to the shape, technical requirements, uses and quantities of the products.

E. process is simple, can be shaped at once, the economic effect is outstanding, especially for the complex shape, difficult to shape a small number of products, more prominent its superior technology.

Two. Disadvantages of glass fiber reinforced plastic flower pots;

1. low modulus of elasticity;

The elastic modulus of FRP is two times larger than the wood, but the ratio of steel (E=2.1 * 106) is 10 times smaller, so in the product structure often feel lack of rigidity, easy deformation, can be made into a thin shell structure, sandwich structure, but also by high modulus fiber or reinforcement form to make up.

2. long term heat resistance is poor;

General FRP can not be used for a long time at high temperature, the general polyester FRP at 50 degrees above, the intensity decreased significantly, generally only under 100 degrees Celsius use; general type epoxy FRP at 60 degrees above, the intensity has decreased significantly. But it is possible to choose the high temperature resistant resin to make the long working temperature at 200~300 centigrade possible.

3. aging phenomenon;

Aging is a common defect of plastics, FRP is no exception, in the ultraviolet, sand, rain and snow, chemical media, mechanical stress, etc., easily lead to performance degradation.

The shear strength between the 4. layers is low

The interlaminar shear strength is borne by the resin, so it is very low. The adhesive force between layers can be improved by choosing the process and using coupling agent. The most important thing is to avoid shearing the interlayer when the product is designed.