Product categories

- Glass fiber reinforced plastic storage tank

- 0

- 0

- Anticorrosion construction of glass fiber reinforced plastics

- Glass fiber reinforced plastic pipe

- 0

- 0

- 0

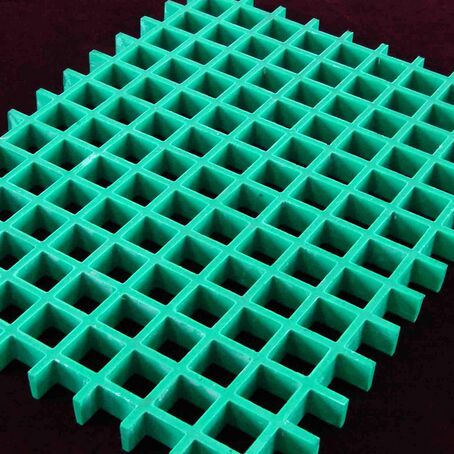

- frp grating

- Jiangsu glass fiber reinforced plastic corrosion protection engineering company

- 0

- diaosu

- 0

- 0

- Integrated prefabricated pumping station

- FRP manufacturers

Contact us

- Add: Suzhou, Changzhou, Wuxi, Shanghai FRP anti-corrosion products

- Tel: 【加微信时须说明您的单位名称和手机号码】

- Fax: 【推销勿扰】【不接同行业务】

- Email: 主要为长三角地区提供玻璃钢防腐制品定制

Product show

Reasons and solutions of glass fiber grating whitening

Product Numbers:201764114726

Price:frp grating

Product introduction:Jiangsu FRP anti-corrosion manufacturers, glass fiber reinforced plastic products - Suzhou, Wuxi, Changzhou, Nantong, Shanghai glass fiber reinforced plastic grille. Glass steel anti-corrosion engineering construction, glass steel

First, glass fiber grating white appear reason

1, the paste itself is not done, it will make the product when the stain appears white.

2, the viscosity of raw materials group is too high, affecting the dispersion stir. Safety glass fiber reinforced plastic grid cover plate

3, resin curing time is short, easy to produce like this fiber infiltration of glass fiber reinforced plastic white spot phenomenon.

4, feed speed is too fast, and finally sucked out the resin, it will produce glass fiber white spots.

5, glass fiber and powder filler dispersion problems, but also very easy to cause glass fiber reinforced plastic leukoplakia.

6, the impact of an inappropriate mechanical external force, resulting in the separation of the local resin and glass fiber glass fiber leukoplakia.

7, the local material by fluorine chemical penetration, and glass fiber cloth point of erosion, forming regular white spots (more serious when can see square). Front Island high pressure pump

8, by improper thermal stress, but also lead to glass fiber reinforced plastic leukoplakia.

Two, glass fiber grating whitening solution

1, from the process to take measures to minimize or reduce excessive machining vibration phenomenon, in order to reduce the role of mechanical forces.

2, especially in the tin lead alloy coating, easy to occur in the gold-plated plug between the plug and chip, must pay attention to choose the appropriate tin, lead drops and operation process.

3, especially hot air leveling, infrared hot melt, such as control failure, will cause thermal stress, resulting in defects in the substrate.

4, check the moisture of the material, in addition to reduce the number of bleeding during the pressing process.

5. Change the diversion pipe or diversion network.

1, the paste itself is not done, it will make the product when the stain appears white.

2, the viscosity of raw materials group is too high, affecting the dispersion stir. Safety glass fiber reinforced plastic grid cover plate

3, resin curing time is short, easy to produce like this fiber infiltration of glass fiber reinforced plastic white spot phenomenon.

4, feed speed is too fast, and finally sucked out the resin, it will produce glass fiber white spots.

5, glass fiber and powder filler dispersion problems, but also very easy to cause glass fiber reinforced plastic leukoplakia.

6, the impact of an inappropriate mechanical external force, resulting in the separation of the local resin and glass fiber glass fiber leukoplakia.

7, the local material by fluorine chemical penetration, and glass fiber cloth point of erosion, forming regular white spots (more serious when can see square). Front Island high pressure pump

8, by improper thermal stress, but also lead to glass fiber reinforced plastic leukoplakia.

Two, glass fiber grating whitening solution

1, from the process to take measures to minimize or reduce excessive machining vibration phenomenon, in order to reduce the role of mechanical forces.

2, especially in the tin lead alloy coating, easy to occur in the gold-plated plug between the plug and chip, must pay attention to choose the appropriate tin, lead drops and operation process.

3, especially hot air leveling, infrared hot melt, such as control failure, will cause thermal stress, resulting in defects in the substrate.

4, check the moisture of the material, in addition to reduce the number of bleeding during the pressing process.

5. Change the diversion pipe or diversion network.