Product categories

- Glass fiber reinforced plastic storage tank

- 0

- 0

- Anticorrosion construction of glass fiber reinforced plastics

- Glass fiber reinforced plastic pipe

- 0

- 0

- 0

- frp grating

- Jiangsu glass fiber reinforced plastic corrosion protection engineering company

- 0

- diaosu

- 0

- 0

- Integrated prefabricated pumping station

- FRP manufacturers

Contact us

- Add: Suzhou, Changzhou, Wuxi, Shanghai FRP anti-corrosion products

- Tel: 【加微信时须说明您的单位名称和手机号码】

- Fax: 【推销勿扰】【不接同行业务】

- Email: 主要为长三角地区提供玻璃钢防腐制品定制

Product show

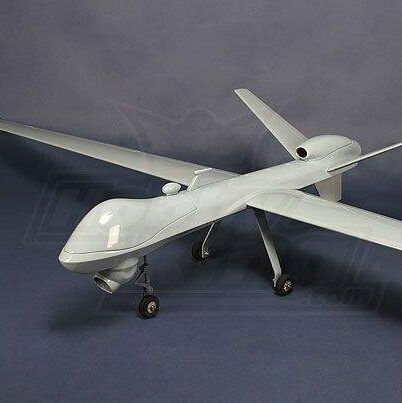

Swiss anti impact drones are made of FRP outside

Product Numbers:2017610141838

Price:FRP corrosion protection

Product introduction:Jiangsu glass steel anti-corrosion glass, steel factory, Suzhou Wuxi Changzhou Nantong Shanghai FRP pipe, glass steel tank, glass steel cooling tower, glass and steel sculpture desulfurization tower, mist purification tower waste

With the rapid development of science and technology, UAVs are not new. But have you ever heard of a drone that could recover itself after the crash? According to the British "Daily Mail" reported on March 13th, double the stiffness characteristics of the Swiss scientist wasp wings (simulation refers wings can switch back and forth in the soft and hard in two), invented an almost irresistible impact of any uav.

The four axis unmanned air vehicle was developed by scientists at the National Research Center of Switzerland and the Federal Institute of technology in Lausanne, switzerland. The UAV outside the framework of this material is glass steel, so that the UAV elastic deformation when subjected to impact or compression, without fracture; internal magnet connected by a center as, to ensure that they maintain the stiffness in normal flight period. After the drone is deformed by the impact, the internal magnet will move its outer frame back and then recover. Tests have proved that the UAV can withstand about 50 strikes without permanent damage. The researchers say the design could allow UAVs to carry more than four rotors

The four axis unmanned air vehicle was developed by scientists at the National Research Center of Switzerland and the Federal Institute of technology in Lausanne, switzerland. The UAV outside the framework of this material is glass steel, so that the UAV elastic deformation when subjected to impact or compression, without fracture; internal magnet connected by a center as, to ensure that they maintain the stiffness in normal flight period. After the drone is deformed by the impact, the internal magnet will move its outer frame back and then recover. Tests have proved that the UAV can withstand about 50 strikes without permanent damage. The researchers say the design could allow UAVs to carry more than four rotors