Product categories

- Glass fiber reinforced plastic storage tank

- 0

- 0

- Anticorrosion construction of glass fiber reinforced plastics

- Glass fiber reinforced plastic pipe

- 0

- 0

- 0

- frp grating

- Jiangsu glass fiber reinforced plastic corrosion protection engineering company

- 0

- diaosu

- 0

- 0

- Integrated prefabricated pumping station

- FRP manufacturers

Contact us

- Add: Suzhou, Changzhou, Wuxi, Shanghai FRP anti-corrosion products

- Tel: 【加微信时须说明您的单位名称和手机号码】

- Fax: 【推销勿扰】【不接同行业务】

- Email: 主要为长三角地区提供玻璃钢防腐制品定制

Product show

You have to know the knowledge of the flue gas scrubber

Product Numbers:201712814929

Price:US $

Product introduction:Jiangsu gas processing equipment manufacturers (Suzhou Wuxi spray tower, spray tower, Changzhou spray tower) glass steel anti-corrosion engineering construction, waste gas purification tower, mist purification tower, mist purifica

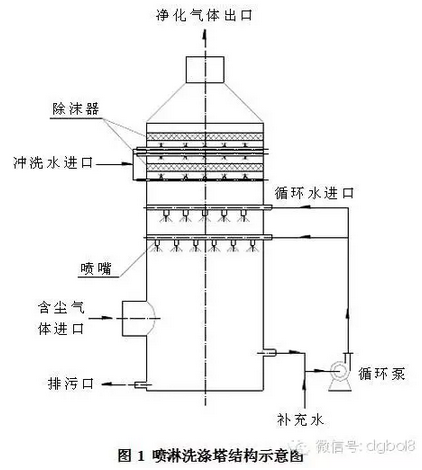

The introduction of acid mist exhaust purification tower by air duct, exhaust gas passes through the filler layer, and sodium hydroxide absorption liquid two-phase full contact absorption neutralization reaction, acid mist emissions after cleaning, the demisting plate dehydration fog by the fan into the atmosphere. The absorption liquid is sprayed at the top of the tower by a water pump, and then is sprayed down to the bottom of the tower. Acid mist emissions after purification reached Guangdong local discharge standard requirements, lower than the national emission standard. You have to know the knowledge of the flue gas scrubber

2 features

1 the efficiency of dust removal and desulfurization is high, the desulfurization efficiency can reach to 85% when using alkaline washing water;

2 equipment area is small, easy to install;

3 water consumption, low power consumption indicators;

4 corrosion resistance, no wear, long service life;

5 the equipment is reliable and easy to maintain.

3 structure

The spray tower filler layer as a component of gas-liquid two phase contact mass transfer equipment. The packing tower with packing support plate, packing to huddle place in the support plate. The filler is installed above the filler plate, in order to prevent rising air blowing. Spray tower spray liquid from the top of the tower by spraying liquid distributor to packing, and the packing surface along the flow. The gas is fed from the bottom of the tower, and is distributed with the liquid through the gas distribution device, and then flows through the gap of the packing layer. When the liquid flows along the packing layer, the wall flow phenomenon sometimes occurs, and the wall flow effect results in the uneven distribution of the gas-liquid two-phase in the packing layer, which leads to the decrease of the mass transfer efficiency. Therefore, the filler layer spray tower is divided into two sections, arranged in the middle of distribution device, the re distribution of spray to lower packing.

4 matters needing attention

1, the cycle of water regulation by spray tower water supply pump to decide, when running a boiler when opening a can, when the winter two or three running at the same time, the two pumps are all opened, the mud pump flow should be based on the circulation pump to adjust the flow, which is equal to.

2, the quantity of chemical spray medicine pool tanega: when running a boiler, adding alkali adding slaked lime 2 bags, 5 bags, such as the winter run two or three units, according to the corresponding increase dosage.

3 spray tower sedimentation tank to be cleaned regularly, once a week to clean up in the summer, the winter three days to clean up once.

4, ash water separator discharge, each class emission once, respectively, to open the drain valve until the water discharge.

5, the rotating parts should always check the oil, and found that failure to promptly eliminate, to ensure the effect of desulfurization spray tower.

6, in the upper and lower stairs when medicine is to Caution!, have independent security, mutual security awareness.

7, the work is completed in a timely manner to clean up the health, so that people go to the venue. You have to know the knowledge of the flue gas scrubber

2 features

1 the efficiency of dust removal and desulfurization is high, the desulfurization efficiency can reach to 85% when using alkaline washing water;

2 equipment area is small, easy to install;

3 water consumption, low power consumption indicators;

4 corrosion resistance, no wear, long service life;

5 the equipment is reliable and easy to maintain.

3 structure

The spray tower filler layer as a component of gas-liquid two phase contact mass transfer equipment. The packing tower with packing support plate, packing to huddle place in the support plate. The filler is installed above the filler plate, in order to prevent rising air blowing. Spray tower spray liquid from the top of the tower by spraying liquid distributor to packing, and the packing surface along the flow. The gas is fed from the bottom of the tower, and is distributed with the liquid through the gas distribution device, and then flows through the gap of the packing layer. When the liquid flows along the packing layer, the wall flow phenomenon sometimes occurs, and the wall flow effect results in the uneven distribution of the gas-liquid two-phase in the packing layer, which leads to the decrease of the mass transfer efficiency. Therefore, the filler layer spray tower is divided into two sections, arranged in the middle of distribution device, the re distribution of spray to lower packing.

4 matters needing attention

1, the cycle of water regulation by spray tower water supply pump to decide, when running a boiler when opening a can, when the winter two or three running at the same time, the two pumps are all opened, the mud pump flow should be based on the circulation pump to adjust the flow, which is equal to.

2, the quantity of chemical spray medicine pool tanega: when running a boiler, adding alkali adding slaked lime 2 bags, 5 bags, such as the winter run two or three units, according to the corresponding increase dosage.

3 spray tower sedimentation tank to be cleaned regularly, once a week to clean up in the summer, the winter three days to clean up once.

4, ash water separator discharge, each class emission once, respectively, to open the drain valve until the water discharge.

5, the rotating parts should always check the oil, and found that failure to promptly eliminate, to ensure the effect of desulfurization spray tower.

6, in the upper and lower stairs when medicine is to Caution!, have independent security, mutual security awareness.

7, the work is completed in a timely manner to clean up the health, so that people go to the venue. You have to know the knowledge of the flue gas scrubber