Product categories

- Glass fiber reinforced plastic storage tank

- 0

- 0

- Anticorrosion construction of glass fiber reinforced plastics

- Glass fiber reinforced plastic pipe

- 0

- 0

- 0

- frp grating

- Jiangsu glass fiber reinforced plastic corrosion protection engineering company

- 0

- diaosu

- 0

- 0

- Integrated prefabricated pumping station

- FRP manufacturers

Contact us

- Add: Suzhou, Changzhou, Wuxi, Shanghai FRP anti-corrosion products

- Tel: 【加微信时须说明您的单位名称和手机号码】

- Fax: 【推销勿扰】【不接同行业务】

- Email: 主要为长三角地区提供玻璃钢防腐制品定制

Product show

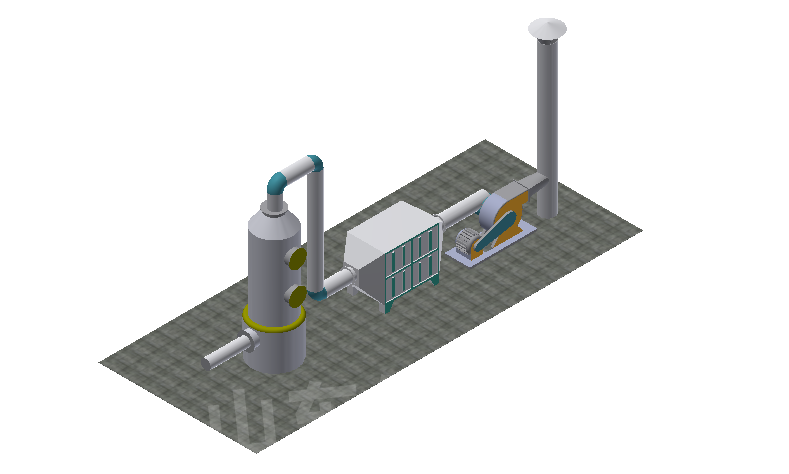

Exhaust gas purification tower. Analysis of organic waste gas treatment process

Product Numbers:201712814184

Price:US $

Product introduction:Jiangsu waste gas purification tower manufacturers (Suzhou Wuxi waste gas purification tower, exhaust gas purification tower, Changzhou gas purification tower, Nantong waste gas purification tower) Shanghai glass steel purificatio

Overview of organic waste gas treatment methods: carbon hydrogen compounds (HC) are one of the most important pollutants in the atmosphere. At present, there are many kinds of gaseous organic pollutants, and there are many kinds of treatment methods, such as absorption, adsorption, catalytic combustion, combustion, condensation and so on. These methods have their own characteristics and advantages and disadvantages, according to the degree of pollution, the use of the environment and conditions to weigh. For environmental inspection agencies and pollution control parties are concerned about: the initial investment costs, operating costs, two pollution, treatment, maintenance and other aspects of the problem. In short, these methods can meet the conditions of gaseous pollutants treatment. The scope and characteristics of the above methods are described as follows. Exhaust gas purification tower. Analysis of organic waste gas treatment process

Organic waste gas adsorption desorption condensation recovery technology

The organic waste gas purification device adopts the method of adsorption and condensation to purify organic waste gas. Give full play to the advantages of high purification efficiency, their disadvantages are available for conversion, adsorbate regeneration using low temperature water vapor adsorption desorption, recovery of body activity of organic compounds desorbed by recycling. For the purification of organic waste gas, this is a more advanced treatment method.

1 scope of application

Organic waste gas purification device for organic waste gas purification treatment in room temperature, low volume, high concentration of organic solvents can be treated including benzene, ketones, esters, alcohols, ethers, aldehydes, alkanes and their mixture. The device can be used in the furniture industry, petrochemical industry, coal chemical industry, artificial leather, textile printing and dyeing, paint and coatings, rubber, plastics, footwear, pharmaceuticals, electronics, chemical fiber, brewing and other industries.

2 working principle

The process can be divided into three stages:

(1) using granular or fibrous activated carbon to fully absorb the organic components of the waste gas, when adsorption to a certain degree of saturation;

(2) at the beginning of the process, the saturated low pressure water vapor was used to heat the saturated activated carbon, and the adsorbed organic components were activated to form the gasification and then removed from the activated carbon. Recovery of activated carbon that can be re adsorbed organic molecules of gas molecules;

(3) the final stage is the condensation of the desorption of the organic component of the gas, so that it is liquefied, and the water is automatically layered and reused.

3 technical features

(1) simple operation, energy saving;

(2) the technology is mature and reliable, stable operation of equipment;

(3) high performance adsorbent, large specific surface area, good adsorption and desorption performance and high purification efficiency;

(4) the safe operation of the equipment system of air temperature exceeds the normal temperature reaches 120 DEG C when the system is equipped with emptying valves, can work automatically according to the system safety program, flow emptying, cut off until the adsorption bed connection termination adsorption desorption process.

Two, adsorption concentration + catalytic oxidation process

Processing method is a combination of adsorption and catalysis, give full play to the advantages of both high purification efficiency, their disadvantages are available for conversion, adsorbate regeneration processing makes use of its catalytic combustion to heat recovery adsorption desorption, body activity, save two energy, and compensation the catalyst of price. For the purification of organic waste gas, this is a more advanced treatment method.

1 scope of application

Organic waste gas purification device for organic waste gas purification treatment in normal temperature, large volume, low concentration, organic solvent can be processed including benzene, ketones, esters, alcohols, ethers, aldehydes, alkanes and their mixture. The device can be widely used in automobile, shipbuilding, motorcycles, bicycles, household appliances, piano, container factory, painting, painting workshop organic waste gas purification, can also be used with shoe glue, tin pot, chemical plastics, printing ink, cable, enameled wire production line supporting the use of.

2 working principle

The process can be divided into three stages:

(1) with special shaped activated carbon to fully absorb the organic components of the exhaust gas molecules, adsorption to a certain degree of saturation when the adsorption is stopped;

(2) at the beginning of the second stage, an additional heater is used to heat a stream of air, and the activated carbon is heated by the hot air to adsorb the saturated activated carbon. Recovery of activated carbon that can be re adsorbed organic molecules of gas molecules;

(3) heating gas on the removal of the organic components, to achieve the required catalytic combustion temperature into the catalytic combustion bed, said here is essentially oxidation combustion, fast and furious under the action of a catalyst, the oxidation of organic molecules of hydrogen and carbon components into CO2 and H2O, and then through the desorption fan, into the adsorbent bed, the molecular organic components until the desorbed were oxidized, the desorption process will be completed. As a result of the oxidation reaction at the same time to release a considerable amount of heat, the device is set up in the heat exchanger, the use of heat to heat up the desorption of the organic component of the gas, and eventually replace the heater work.

3 technical features

(1) full automatic control, easy operation, energy saving;

(2) no flame oxidation, high purification efficiency, safe and efficient operation of equipment;

(3) high catalytic activity, stable performance, low resistance;

(4) high performance activated carbon adsorbent with large specific surface area, good absorption and desorption performance, small wind resistance. Exhaust gas purification tower. Analysis of organic waste gas treatment process

Organic waste gas adsorption desorption condensation recovery technology

The organic waste gas purification device adopts the method of adsorption and condensation to purify organic waste gas. Give full play to the advantages of high purification efficiency, their disadvantages are available for conversion, adsorbate regeneration using low temperature water vapor adsorption desorption, recovery of body activity of organic compounds desorbed by recycling. For the purification of organic waste gas, this is a more advanced treatment method.

1 scope of application

Organic waste gas purification device for organic waste gas purification treatment in room temperature, low volume, high concentration of organic solvents can be treated including benzene, ketones, esters, alcohols, ethers, aldehydes, alkanes and their mixture. The device can be used in the furniture industry, petrochemical industry, coal chemical industry, artificial leather, textile printing and dyeing, paint and coatings, rubber, plastics, footwear, pharmaceuticals, electronics, chemical fiber, brewing and other industries.

2 working principle

The process can be divided into three stages:

(1) using granular or fibrous activated carbon to fully absorb the organic components of the waste gas, when adsorption to a certain degree of saturation;

(2) at the beginning of the process, the saturated low pressure water vapor was used to heat the saturated activated carbon, and the adsorbed organic components were activated to form the gasification and then removed from the activated carbon. Recovery of activated carbon that can be re adsorbed organic molecules of gas molecules;

(3) the final stage is the condensation of the desorption of the organic component of the gas, so that it is liquefied, and the water is automatically layered and reused.

3 technical features

(1) simple operation, energy saving;

(2) the technology is mature and reliable, stable operation of equipment;

(3) high performance adsorbent, large specific surface area, good adsorption and desorption performance and high purification efficiency;

(4) the safe operation of the equipment system of air temperature exceeds the normal temperature reaches 120 DEG C when the system is equipped with emptying valves, can work automatically according to the system safety program, flow emptying, cut off until the adsorption bed connection termination adsorption desorption process.

Two, adsorption concentration + catalytic oxidation process

Processing method is a combination of adsorption and catalysis, give full play to the advantages of both high purification efficiency, their disadvantages are available for conversion, adsorbate regeneration processing makes use of its catalytic combustion to heat recovery adsorption desorption, body activity, save two energy, and compensation the catalyst of price. For the purification of organic waste gas, this is a more advanced treatment method.

1 scope of application

Organic waste gas purification device for organic waste gas purification treatment in normal temperature, large volume, low concentration, organic solvent can be processed including benzene, ketones, esters, alcohols, ethers, aldehydes, alkanes and their mixture. The device can be widely used in automobile, shipbuilding, motorcycles, bicycles, household appliances, piano, container factory, painting, painting workshop organic waste gas purification, can also be used with shoe glue, tin pot, chemical plastics, printing ink, cable, enameled wire production line supporting the use of.

2 working principle

The process can be divided into three stages:

(1) with special shaped activated carbon to fully absorb the organic components of the exhaust gas molecules, adsorption to a certain degree of saturation when the adsorption is stopped;

(2) at the beginning of the second stage, an additional heater is used to heat a stream of air, and the activated carbon is heated by the hot air to adsorb the saturated activated carbon. Recovery of activated carbon that can be re adsorbed organic molecules of gas molecules;

(3) heating gas on the removal of the organic components, to achieve the required catalytic combustion temperature into the catalytic combustion bed, said here is essentially oxidation combustion, fast and furious under the action of a catalyst, the oxidation of organic molecules of hydrogen and carbon components into CO2 and H2O, and then through the desorption fan, into the adsorbent bed, the molecular organic components until the desorbed were oxidized, the desorption process will be completed. As a result of the oxidation reaction at the same time to release a considerable amount of heat, the device is set up in the heat exchanger, the use of heat to heat up the desorption of the organic component of the gas, and eventually replace the heater work.

3 technical features

(1) full automatic control, easy operation, energy saving;

(2) no flame oxidation, high purification efficiency, safe and efficient operation of equipment;

(3) high catalytic activity, stable performance, low resistance;

(4) high performance activated carbon adsorbent with large specific surface area, good absorption and desorption performance, small wind resistance. Exhaust gas purification tower. Analysis of organic waste gas treatment process